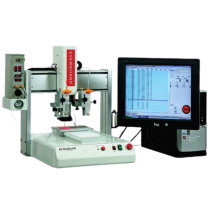

ES300VR Smart visual 3-axis positioning platform

The VR series adopts modulized casing structure incorporated with precision belt-rail module to achieve precise and stable efficacy throughout the machine, which also has advantages of light weight and small volume.By using highly efficient computer as the control platform and incorporating with CCD, users can plan processing paths on the computer screen easily.The accurate visual positioning and identification system can further adjust routes automatically, which reduces errors of repetitively placing objects on the jig, and monitoring of processing rate.The visualized operation interface reduces threshold of learning, and enhances the planning efficiency for processing. The machine also comes in specification of 400X400 or other customization request. Calling for inquiry is welcomed.

| Specifications |

|||

| processing range |

300/300/100(mm) |

Movement interpolation |

3-axis simultaneous movement (3D space) |

| Maximum load |

XY 10kg Z 5kg |

Programmed capacity |

Infinite sets/ Supports AUTOCAD-DXF |

| Moving speed |

XY 0.1~450 / Z 250(mm/sec) |

Editing mode |

Operating computer incorporated with CCD camera |

| Resolution |

0.01mm |

Visual positioning |

Image identification/ Automatic compensation |

| Repetition precision |

+/- 0.02mm |

IO port |

8 Input/8 Output |

| Motor system |

Precision micro-stepping motor |

Input power |

AC110~220V 150W |

| Transmission method |

XY: belt-rail, Z: Precision screw |

Dimensions and weight |

W485xL500xH600mm 35kg |